Internetowy sklep akwarystyczny

Zapoznaj się z ofertą

Bestsellery

O nas

Jesteśmy internetowym sklepem akwarystycznym z wieloletnim doświadczeniem w branży. Zajmujemy się sprzedażą produktów związanych z hodowlą ryb i innych zwierząt wodnych, takich jak akwaria, filtry, pokarmy czy dekoracje. Nasza firma powstała dzięki pasji do akwarystyki i trosce o dobrostan naszych podopiecznych. Polecamy obstawianie

Internetowy sklep akwarystyczny

Wszystko dla Twojego akwarium

W dzisiejszych czasach wiele ludzi decyduje się na posiadanie domowego akwarium, które może stać się zarówno ozdobą mieszkania, jak i hobby pozwalającym wypocząć po ciężkim dniu. Jednak, aby utrzymać dobry stan oraz zdrowie ryb i roślin akwariowych niezbędne są odpowiednie akcesoria oraz środki do ich pielęgnacji. Właśnie dlatego powstał internetowy sklep akwarystyczny, który oferuje bogatą gamę produktów potrzebnych każdemu miłośnikowi hodowli rybek.

W naszej ofercie znajdziesz wszelkiego rodzaju filtry, systemy oświetleniowe spośród najnowszych technologii LED, a także pokarmy i preparaty czyszczące dedykowane różnym gatunkom ryb. Ponadto proponujemy również dekoracje gwarantujące piękno twojemu zbiornikowi. Odpowiednio dobrany sprzęt to podstawa pomyślnego rozwoju i wzrostu ryb w przestrzeni przydomowej.

Akcesoria taniej niż w sklepie stacjonarnym

Każdy akwarysta wie, że utrzymanie akwarium w prawidłowym stanie wymaga zarówno czasu, jak i pieniędzy. Jednak korzystając z internetowego sklepu akwarystycznego można zaoszczędzić sporo gotówki podczas zakupów niezbędnego wyposażenia. Ceny produktów oferowanych przez taki sklep są na ogół niższe niż te, które spotkać można w stacjonarnych punktach sprzedaży. Co więcej, internetowe sklepy często organizują atrakcyjne promocje i rabaty dla swoich klientów.

Polecamy również https://milobuty.pl/

Wysoka jakość sprzętu i pozytywne opinie innych klientów to niewątpliwie czynniki, które przemawiają za tym rodzajem zakupów. Dostępny asortyment jest ogromny – nie tylko różnorodność gatunkowa ryb czy roślin dostarcza zadowolenia miłośnikom tego hobby. Wszelkiego rodzaju filtry, grzałki oraz preparaty do pielęgnacji wody są tu dostępne bez potrzeby opuszczenia domu. Kupując online oszczędzasz czas – nie tracisz go na dojazd do sklepu ani na szukanie odpowiednich produktów pomiędzy mnóstwem innych artykułów – a także przeważnie otrzymujesz zamówione produkty szybciej niż przy standardowych zakupach stacjonarnych.

Darmowa dostawa od 900 złotych

W dzisiejszych czasach zakupy przez Internet są już czymś rutynowym. Coraz więcej sklepów stawia na sprzedaż online, a to z kolei prowadzi do wzrostu konkurencji. Dlatego też, coraz więcej e-sklepów decyduje się na wprowadzenie darmowej dostawy powyżej określonego progu zamówienia. W tym przypadku mowa o internetowym sklepie akwarystycznym, który oferuje swoim klientom darmową przesyłkę od kwoty 900 zł.

Korzystanie z takiej opcji ma wiele zalet. Po pierwsze, oszczędza czas i pieniądze – nie trzeba szukać sposobu na uniknięcie kosztów wysyłki czy rozważać, czy warto dokupić jeszcze coś do zamówienia w celu przebicia limitu. Po drugie, korzystając z darmowej dostawy można łatwiej planować zakupy i zbierać potrzebne artykuły przez dłuższy czas – bez presji konieczności ponoszenia kosztów przesyłki przy każdej osobnej transakcji. W awaryjnych sytuacjach nasze zamówienia dowozi Pomoc drogowa Słubice

Największy wybór roślin

Internetowy sklep akwarystyczny to idealne miejsce dla miłośników natury i piękna. W ofercie sklepu znajduje się największy wybór roślin z całego świata. Możesz znaleźć zarówno klasyczne, popularne gatunki jak i te trudniejsze do uprawy. Dzięki temu, każdy miłośnik akwarystyki może urządzić swój zbiornik według własnego gustu oraz potrzeb swoich podopiecznych.

W internetowym sklepie akwarystycznym możesz też liczyć na fachowe doradztwo ekspertów. Nasi pracownicy służą pomocą przy wyborze roślin takiego rodzaju, który będzie najlepiej pasował do ilości światła czy temperatury w Twoim akwarium.

Promocje na sprzęt filtracyjny

Promocje na sprzęt filtracyjny to idealna okazja dla wszystkich miłośników akwarystyki, którzy chcą ulepszyć swoje zbiorniki wodne. W naszym internetowym sklepie akwarystycznym znajdziesz szeroki wybór filtrów i akcesoriów do nich w najlepszych cenach na rynku. Profesjonalny system filtracji to podstawa dobrej jakości wody w akwarium, co ma kluczowe znaczenie dla zdrowia ryb i roślin. Dzięki naszym promocjom nie tylko zadbasz o zdrowie Twoich ulubionych podopiecznych, ale też zaoszczędzisz sporo pieniędzy, które można przeznaczyć np. na kolejne dekoracje lub nową populację rybek!

Nie czekaj dłużej i zapoznaj się z ofertą naszego sklepu! Oferujemy różnorodne filtry wewnętrzne i zewnętrzne odpowiednie dla każdego typu akwarium, a także kaskadowe filtry kanistrowe i specjalistyczne systemy biologicznej filtracji. Zadbaj o jakość życia Twoich ryb i wybierz sprawdzony sprzęt, który zapewni im komfort i bezpieczeństwo przez długi czas.

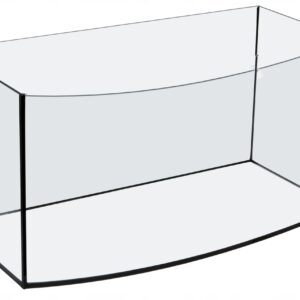

Akwaria

Akwaria to jedne z najczęściej wybieranych przydomowych ozdób. Wymagają odpowiedniej pielęgnacji i dbałości, dlatego warto udać się do specjalistycznego sklepu akwarystycznego. Internetowy sklep akwarystyczny oferuje szeroką gamę akwariów różnej wielkości, kształtu i z różnymi rodzajami oświetlenia. Znajdziemy tu tradycyjne, proste szklane boksy oraz efektowne eleganckie szafki na wymiar z podświetleniem LED.

Ponadto, oferta internetowego sklepu akwarystycznego to nie tylko same akwaria – można tam znaleźć także sprzęt niezbędny do ich utrzymania w doskonałej kondycji jak filtry, pompy powietrza czy grzałki. Wszyscy miłośnicy hodowli rybek znajdą również bogaty asortyment pokarmów oraz dodatków umożliwiających ozdobienie naszego małego ekosystemu. Takie miejsce sprawi, że podejmowanie decyzji o zakupie stanie się prostsze – dzięki temu jedno miejsce zaopatrywania możemy oszczędzić czas i pieniądze.

Filtry

Filtry to jedne z podstawowych akcesoriów akwarystycznych, a właśnie w Internetowym sklepie akwarystycznym znajdziesz szeroki wybór najlepszych jakościowo filtrów. Bez odpowiedniego filtra, Twoje akwarium stanie się miejscem niezdrowych warunków dla ryb i roślin. Filtracja wody zapewnia optymalne warunki do życia Twoich podopiecznych – zatrzymuje zanieczyszczenia i nadaje czystość wodzie.

Internetowy sklep akwarystyczny posiada różnego rodzaju filtry do zarówno małych jak i dużych akwariów, dzięki temu możesz łatwo znaleźć idealnie dopasowany do swojego wymiaru i liczby mieszkańców zbiornika. W ich ofercie wszystkie typy filtracji: mechanicznej, biologicznej, chemicznej oraz kombinowanej. Jeśli potrzebujesz pomocy w dobraniu odpowiedniego filtra lub innych urządzeń, zawsze możesz skontaktować się ze specjalistami Internetowego sklepu akwarystycznego.

Pokarmy

W internetowym sklepie akwarystycznym istotną kategorię produktów stanowią pokarmy dla ryb. Asortyment jest bardzo szeroki, a co najważniejsze – różnorodny. Dzięki temu każdy hodowca będzie miał możliwość doboru pożywienia odpowiedniego dla swoich podopiecznych.

Różne rodzaje pokarmów oferowane w tym sklepie to np. : granulaty, płatki, tabletki i liofilizowane kawałki mięsa czy warzyw. Ważne jest także, aby właściciele dbali o wartości odżywcze i balans diety swoich ryb oraz by unikać nadmiernego dokarmiania. Warto wybrać sprawdzonych producentów oraz regularnie zmieniać rodzaj podawanego pożywienia dla zapewnienia naszym ulubieńcom zróżnicowanego menu i odpowiedniej dawki witamin.

Dekoracje.

W ofercie internetowego sklepu akwarystycznego znajdziesz szeroki wybór dekoracji do Twojego akwarium. Odpowiednio dobrana ozdoba nie tylko podkreśli naturalny wygląd zbiornika, ale także poprawi warunki życia zwierząt. W asortymencie sklepu dostępne są zarówno kamienie i korzenie, jak i sztuczne rośliny oraz ceramiczne groty.

Dekoracje służą nie tylko celom estetycznym, ale również wpływają na jakość wody w akwarium. Kamienie i korzenie zmniejszają twardość wody, co jest korzystne dla ryb pochodzących z kwaśnych jezior lub rzek. Sztuczne rośliny z kolei stanowią schronienie dla małych rybek i przyczyniają się do utrzymania stabilnej ekosystemu.

Podsumowanie

Internetowy sklep akwarystyczny to świetne rozwiązanie dla miłośników akwarystyki. Dzięki bogatej ofercie produktów dostępnych online, możemy szybko i wygodnie zaopatrzyć się w potrzebne rzeczy do naszego hobby. Wiele sklepów internetowych oferuje także doradztwo techniczne oraz fachowe porady, co pozwala na sprawną realizację planowanych projektów. Bez wychodzenia z domu można zamówić różnego rodzaju pokarmy i suplementy diety dla ryb, niezbędne narzędzia czy ozdoby do aranżacji zbiornika. To rozwiązanie dedykowane zarówno początkującym jak i zapalonym miłośnikom wodnego świata.

Zanurz się w akwarystyczny świat – internetowy sklep dla pasjonatów – FAQ

Jakie produkty oferuje Internetowy sklep akwarystyczny?

Internetowy sklep akwarystyczny oferuje szeroki wybór produktów związanych z akwarystyką, w tym: akwaria, filtry, pompy, oświetlenie, pokarm dla ryb oraz dekoracje.

Czy można liczyć na fachową poradę pracowników sklepu?

Tak, pracownicy Internetowego sklepu akwarystycznego są dobrze przeszkoleni i chętnie udzielają porad dotyczących wyboru właściwych produktów oraz dbałości o ryby i rośliny w akwarium.

Jak dokonać zakupów w Internetowym sklepie akwarystycznym?

Można dokonać zakupów poprzez stronę internetową sklepu. Wystarczy wybrać interesujące nas produkty i dodać je do koszyka. Następnie należy przejść do formularza zamówienia i podać niezbędne dane do wysyłki.

Jakie są koszty dostawy zamówienia?

Koszt dostawy zależy od wielkości i wagi zamówionych produktów oraz miejsca docelowego. Koszty dostawy są podane przed potwierdzeniem finalnego zamówienia.

Czy istnieje możliwość zwrotu zamówionego towaru?

Tak, klient ma prawo do zwrotu zamówionego towaru bez podawania przyczyny w ciągu 14 dni od otrzymania przesyłki. Warunkiem jest zachowanie stanu produktu zgodnego z jego pierwotnym przeznaczeniem oraz niewykorzystanie go.